FORT KNOX, Ky. – Throughout Cadet Summer Training, Shower and Laundry Specialists from Puerto Rico standby to provide warm showers and clean laundry for Cadets who are training in the field.

Spc. Carlos Osorio operates a LADS at Fort Knox, Ky., July 23, 2019. | Photo by Mary Kate Griffin, CST Public Affairs Office.

For many of the specialists, this summer is their first time at Fort Knox. The nature of Cadet Summer Training (CST) operations provides a unique experience for them as their mission is uninterrupted by tactical operations.

“We have had assignments in places where we needed to have security,” said 1st Lt. Bianca Viruet, referring to combat deployments the 430th Quartermaster Co. participated in over the years. “Tactical situations shift our focus from laundry to defense.”

Without the distraction of combat here, laundry specialists are able to receive a truck-load of dirty laundry, wash it, dry it, and returned to the Cadets all within 72 hours.

This turnaround is made possible because of the stringent organizational system the specialists use as well as the efficiency of the machines that wash and dry the laundry.

Logistics and Paper Trails: The System

Laundry specialists inprocess dirty laundry from Advanced Camp Cadets at Fort Knox, Ky., July 23, 2019. | Photo by Mary Kate Griffin, CST Public Affairs Office.

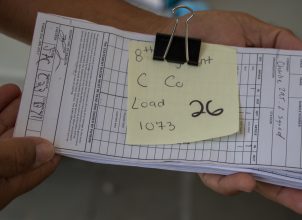

More surprising than the 1,073 loads of laundry the specialists have washed already this summer is that the clothing in each load is accounted for using an analog system.

Before laundry is sent to the specialists to be cleaned, Cadets fill out a paper form detailing the type and quantity of each clothing article along with their assigned regiment, platoon and squad. Dirty clothing is stuffed into canvas bags, loaded onto a truck and sent to the Logistics Support Area (LSA) Pickett site.

Once the dirty laundry arrives on site, specialists load the bags into rolling bins that are brought into a tent with four rows of open cardboard boxes. The canvas bags are placed into a cardboard box that is labeled with their regiment’s number until they are itemized.

When the specialists are ready to begin itemization, the bags are placed into a rolling bin and wheeled to the in-processing tent. Upon arrival, the bins are labeled with their regiment number on a strip of duct tape.

“We label the bins this way because it is an easy way to track where the laundry is at any given time,” said Staff Sgt. Jonathan Cabrera, NCOIC of in-processing the laundry. “After in-processing, we peel the tape off the bin and stick it next to the laundry advanced system (LADS) where the laundry is being cleaned.”

A stack of 8th Regiment, Advanced Camp itemized laundry forms at Fort Knox, Ky., July 23, 2019. | Photo by Mary Kate Griffin, CST Public Affairs Office. This stack represents the 1,073rd load of laundry to be washed during CST 2019!

During in-processing, the canvas bags are emptied and checked for the items that are stated on the forms Cadets filed. Contents are then itemized, marked as present on their forms and stuffed into mesh bags with numbers corresponding with their respective Cadets.

One specialist is designated to collect all the forms and ensure that they are sent back with the regiment’s laundry once it is cleaned.

“I have someone different collect the paper work every time,” said Cabrera. “I do this so that if I am ever absent the other specialists know how to do it.”

All of the information that is received through in-processing is recorded in a master book about an inch thick. The specialists have used up to three master books for CST operations alone.

The Dirty Work

An exterior view of two drum windows looking into a laundry advanced system (LADS) at Fort Knox, Ky., July 23, 2019. | Photo by Mary Kate Griffin, CST Public Affairs Office.

The machines the specialists use to wash and dry the Cadets’ laundry do not look like conventional appliances. Laundry advanced systems (LADS) are large trailers that run on diesel fuel and have two separate drums, each drum capable of washing and drying the same load in just one hour.

LADS draw their water from an inflatable bladder, which can hold up to 3,000 gallons of water. Filters in the LADS recycle water that has been used in previous cycles to be used in later cycles.

“After each cycle, dirty water is filtered and reused for subsequent cycles,” said Spc. Carlos Osorio, a laundry specialist. “The only time clean water is introduced is during the pre-wash cycle. This initial cycle removes excess filth from the laundry and none of the water is reused.”

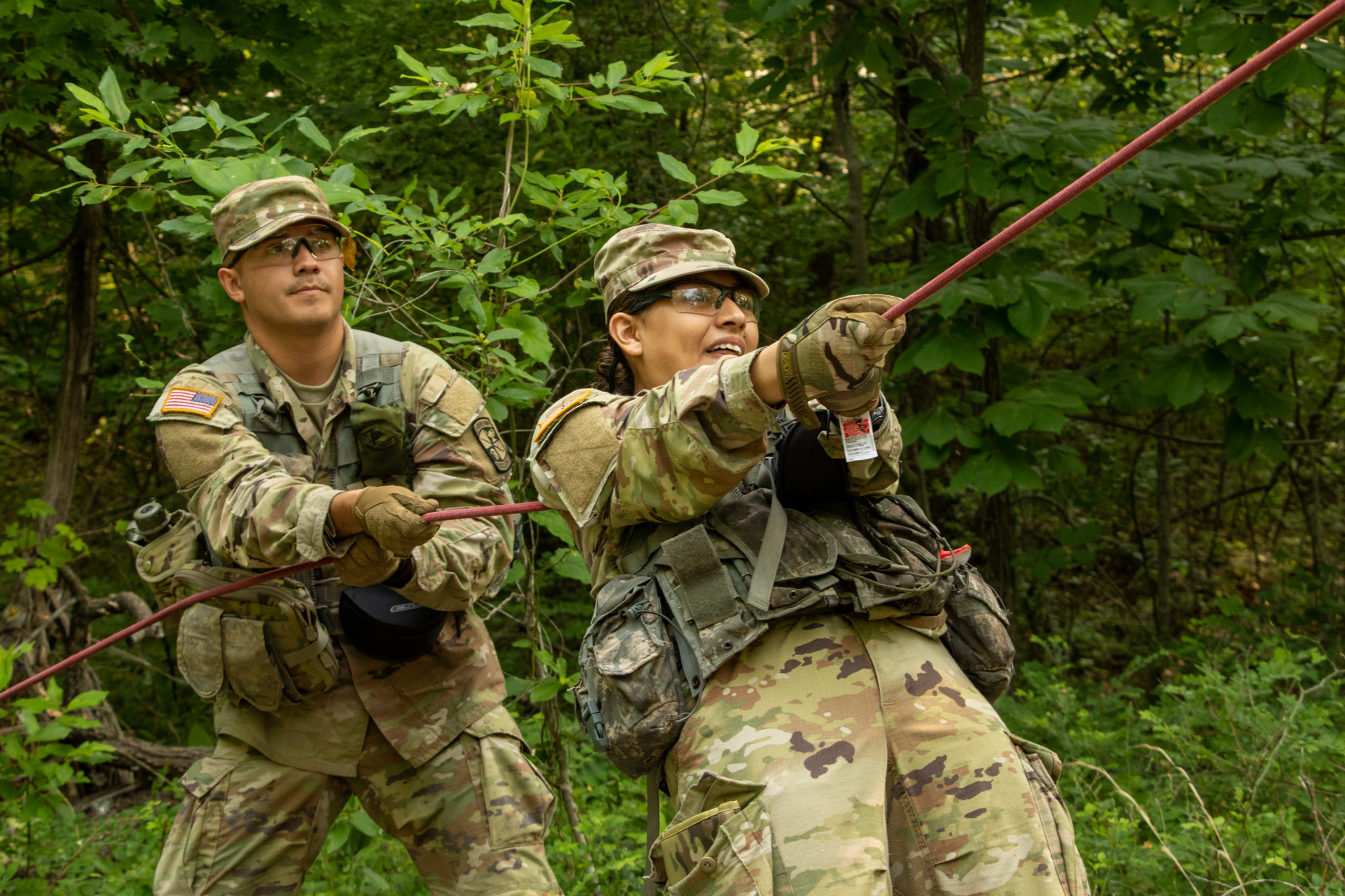

The pre-wash cycle is especially needed when Cadets’ uniforms have been soiled while out in the field. While in the dense woods during their field training exercises (FTX), Cadets must live in the same uniform for roughly a week at a time. The thoroughness of the LADS’ cycle capabilities leaves laundry as good as new.

An Eco-Friendly Spin

A laundry specialist cleans the laundry advanced system (LADS) at Fort Knox, Ky., July 23, 2019. | Photo by Mary Kate Griffin, CST Public Affairs Office.

Every three to four days, Laundry Advanced Systems (LADS) are thoroughly cleaned with a bio-based formula cleanser that is biodegradable, environmentally non-toxic and free of volatile organic compounds (VOC’s) that contribute to greenhouse gas emissions.

“We use up enough resources as it is,” said Viruet, the OIC (Officer in Charge) of the operation. “We do what we can to compensate for this by using ‘green’ products.”

To eliminate dirty water runoff, specialists crafted a PVC pipe system for all hoses connected to the LADS to drain water waste at a designated spot. This prevents wildlife from accidentally drinking toxic water.

The Shower Situation

A row of showers on the LSA Pickett site at Fort Knox, Ky., July 23, 2019. | Photo by Mary Kate Griffin, CST Public Affairs Office.

The showers at the LSA Pickett site are for Cadets that are returning from field training. While at LSA Pickett, Cadets can shower and get their laundry cleaned.

“Showers are limited to seven minutes per Cadet,” said Sgt. Josué Colón Dávila, the NCOIC of shower operations. “We also tell Cadets to remove their boots and OCP (operational camo pattern) blouse ahead of time. With these measures, we are able to get an entire regiment of Cadets showered in about an hour and a half.”

The specialists inserted more curtains and turned the showers to face away from each other to provide privacy for the Cadets.

“We want Cadets to feel comfortable here,” said Viruet.